Category:

- Product Description

Meat packaging bag

-

- Commodity name: Meat packaging bag

Brief Description: Meat product packaging is designed to ensure the freshness, hygiene, and safety of meat, while facilitating storage, transportation, and sales. It's a protective covering specifically designed for meat, with the core purpose of safeguarding meat quality, safety, and hygiene at every stage, and providing convenient storage and sales methods. For example, various packaged pork, beef, chicken, etc., commonly seen in the market, all rely on appropriate packaging.

Meat product packaging is the packaging material used to wrap and protect meat.

Brief Description:

Meat product packaging is designed to ensure the freshness, hygiene, and safety of meat, while facilitating storage, transportation, and sales. It is a protective covering specifically designed for meat. Its core purpose is to safeguard the quality, safety, and hygiene of meat at every stage, and to provide convenient storage and sales methods.

For example, various packaged pork, beef, and chicken products commonly seen in the market all rely on appropriate packaging.

Detailed Description of Meat Product Packaging

The materials used in meat product packaging are usually carefully selected and combined. Polyethylene (PE), with its excellent flexibility and moisture resistance, is often used for the inner layer in contact with meat; Polypropylene (PP), with its high strength and heat resistance, provides structural support for the packaging; Polyester (PET) has good transparency and barrier properties, helping to showcase the appearance of the meat and prevent the penetration of external gases; Nylon (PA), with its high strength and excellent oxygen barrier properties, plays a key role in composite packaging.

In terms of bag types, vacuum bags, by removing air to create an oxygen-free environment, greatly extend the shelf life of meat, especially suitable for long-distance transportation and long-term storage; Modified atmosphere packaging (MAP) bags can precisely adjust the internal gas composition, such as increasing the carbon dioxide content to inhibit bacterial growth, maintaining the color and taste of the meat; Skin packs closely fit the shape of the meat, not only presenting a realistic appearance but also effectively preventing blood leakage; Three-side sealed bags and stand-up pouches ensure sealing while facilitating display and consumer access.

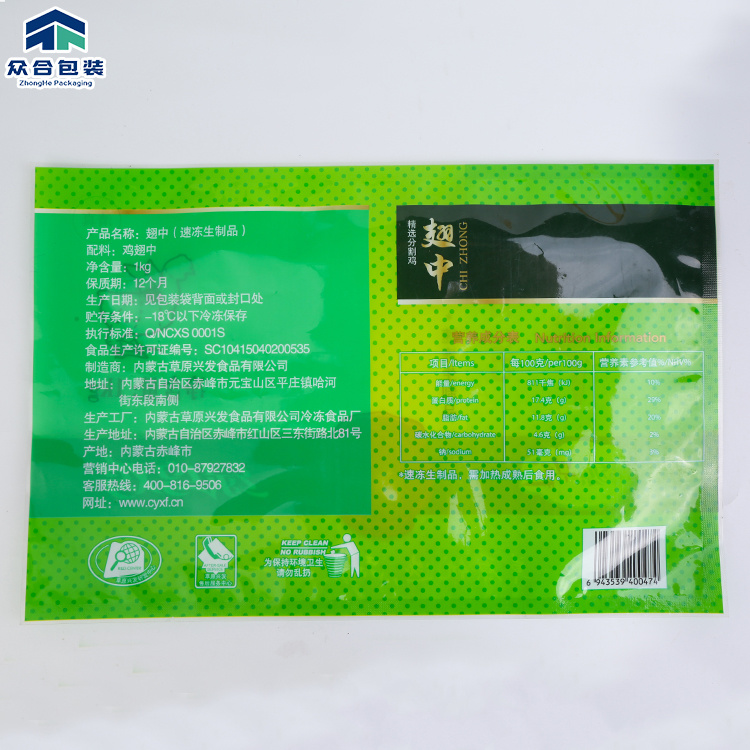

In addition, meat product packaging also considers properties such as oil resistance and low-temperature resistance. The printing on the packaging surface usually includes important information such as the type of meat, origin, shelf life, and processing method, for consumers to understand and choose.

For example, the packaging of a fresh beef product might use a PA/PE composite structure, with a modified atmosphere packaging bag type, clearly indicating the beef's origin and freshness date on the print.

It is made using specific materials and processes based on the characteristics of the meat and market demand.

Why is it called meat product packaging?

Because it is specifically created and defined to meet the packaging needs of this special food, meat. Its functions, materials, and design all revolve around the characteristics of meat.

What types of bags are used for meat product packaging?

Common meat product packaging bag types include:

Vacuum bags: Vacuuming reduces oxygen, extending the shelf life of meat.

Modified Atmosphere Packaging (MAP) bags: Adjust the internal gas ratio to optimize freshness.

Skin packs: Closely fit the meat, highlighting its shape.

Three-side sealed bags: Three sides are sealed, simple structure and good sealing.

Stand-up pouches: Can stand upright, convenient for display and storage.

Material Parameters and Characteristics of Meat Product Packaging

Characteristics:

Good barrier properties, preventing the entry of oxygen, moisture, and microorganisms.

Oil and puncture resistant, preventing blood and oil leakage.

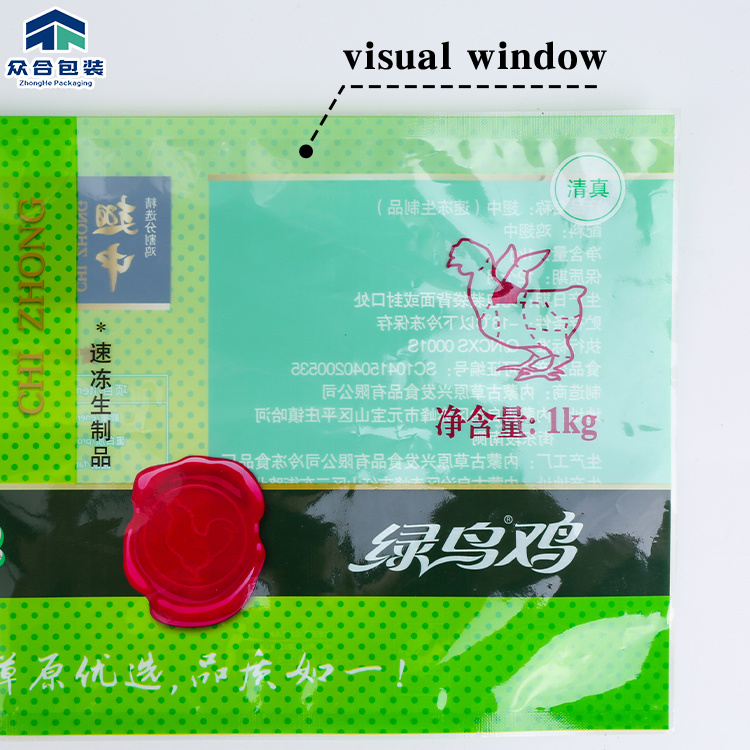

Appropriate transparency, allowing consumers to observe the quality of the meat.

Complies with food safety standards, non-toxic and odorless.

Material Parameters:

The thickness of the film is generally between 0.08mm and 0.2mm, selected according to different meat types and preservation requirements.

Oxygen permeability is usually required to be below 50cm³/(m²•24h•0.1MPa) to reduce oxidation.

Water vapor permeability should be below 5g/(m²•24h) to prevent moisture loss.

Tensile strength should be greater than 20MPa to ensure that the packaging is not easily broken.

Meat Product Packaging Processing Flow

Material Procurement: Selecting raw materials such as PE, PP, PET, and PA that meet food contact standards and preservation requirements.

Printing and Design (if needed): Designing and producing printing plates according to customer requirements, using environmentally friendly inks for printing.

Lamination: Combining films of different materials through adhesives or co-extrusion to create packaging materials with comprehensive performance.

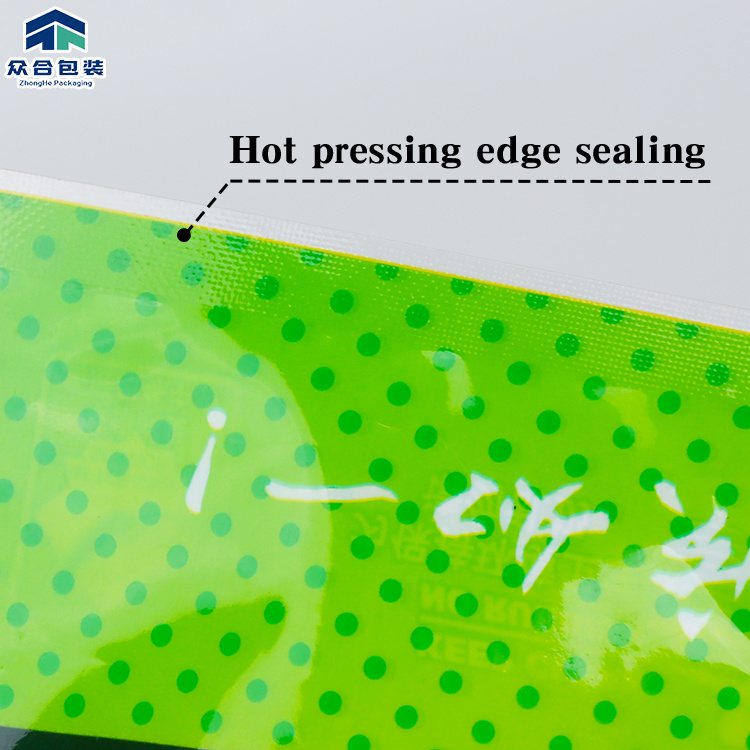

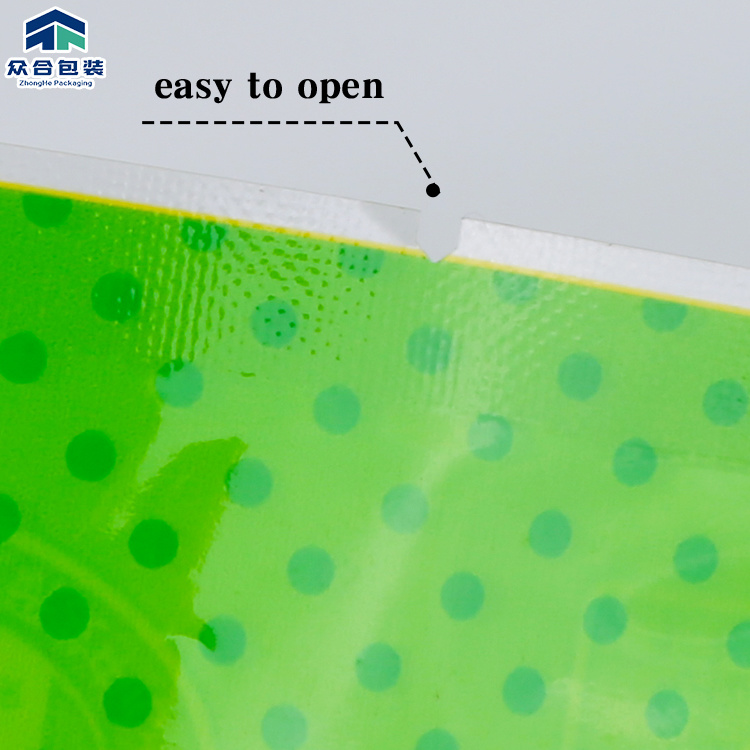

Bag Making: Using bag-making equipment to process the laminated materials into vacuum bags, MAP bags, skin packs, and other bag types, and performing heat sealing or other sealing treatments.

Sterilization and Disinfection (some products): For some meat packaging with strict requirements, sterilization and disinfection are performed to ensure the sterile state of the packaging.

Quality Inspection: Conducting comprehensive quality inspections of the produced meat product packaging, including inspections of appearance, dimensions, seal strength, and barrier performance.

Packaging: Organizing, counting, and packaging qualified products, preparing for delivery to customers.

Our Advantages

As a manufacturer, we have the following significant advantages:

Advanced Production Technology: We possess advanced production equipment and technology, capable of producing high-quality, high-performance meat product packaging.

Strict Quality Control: From raw material procurement to finished product delivery, we have established a strict quality control system to ensure that every product meets high standards.

Customized Service: We can provide personalized packaging solutions based on customer's specific needs, meeting the requirements of different meat products and markets.

Cost-Effectiveness: By optimizing production processes and management, we effectively reduce production costs, providing customers with competitive prices.

Rapid Market Response: We closely monitor market dynamics and customer needs, and can quickly adjust production strategies to promptly launch new products that meet market trends.

What does meat product packaging bring to customers?

For customers, our meat product packaging can bring the following important value:

Improved Freshness: Significantly extends the freshness and shelf life of meat, reducing losses due to spoilage.

Quality Assurance: Maintaining the original color, flavor, and nutritional content of the meat, improving consumer satisfaction.

Brand Image Building: Exquisite packaging design and high-quality material selection help enhance customer brand image and market competitiveness.

Sales Promotion: Attracting consumer attention and desire to purchase, increasing sales volume and market share.

Application Scope of Meat Product Packaging

Meat product packaging is widely used in the following areas:

Fresh Meat: such as fresh pork, fresh beef, fresh mutton, etc.

Frozen Meat: including frozen chicken, frozen fish, frozen beef, etc.

Processed Meat: such as ham, sausage, bacon, etc.

Supermarkets: In the retail sector, providing consumers with neatly and hygienically packaged meat products.

Farmers' markets: facilitating the display and sale of meat by meat vendors.

Meat processing plants: used for mass production and packaging of various meat products.

Catering businesses: providing restaurants, canteens, etc., with safe and convenient meat packaging.

Online Consultation

Contact us immediately for free expert consultation services!

Related Products

Haijun Zhang

Haijun Zhang

WhatsApp (Mia)

WhatsApp (Mia)